Breather and Sampling Point Audit - Nth Queensland

Date: April 2020

Project: Breather and Sampling Point Audit - North Queensland

Contact: Mechanical Engineer

Report By Jesse Ravlen

1.0 Background

GOSS Engineering have been undertaking lubrication servicing on Mining Plant and Equipment for over a decade, within this time we have seen what the consistent presence of dirt, water and contaminants can do to Oil Systems and their rotating and sliding elements. Inevitably this can lead to large amounts of downtime and loss of production when the plant fault or fail.

This site in Queensland had requested that we undertake an audit on their current Breather and Sampling Points, to identify opportunities to improve the cleanliness of the air entering the compartments, oil and the accuracy and process of taking oil samples. The audit found that the current Breather and Sampling Points weren’t at the optimal standard to minimise risk of moisture, debris or coal dust getting into the Oil Systems and not only damaging to the machinery but giving inaccurate Oil Samples results.

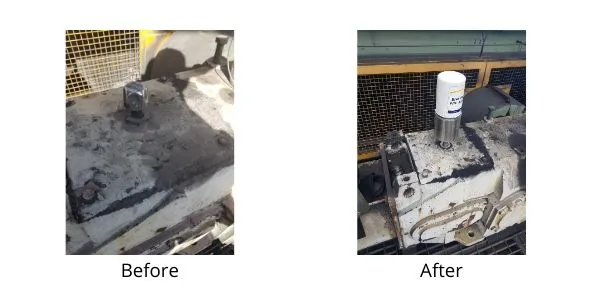

Example 1 - Oil Samples were being taken from the orifice where the dip stick is being removed in Figure 1, which allows the possibility for build-up of dirt, coal and dust to enter the system every time that dip stick is removed; this also leads to inaccurate Oil Samples.

Oil Sampling

Correctly installed sample points have insured that a sample is taken from the same point each time and that the oil is extracted from the same depth in the compartment each time. Ingress of dirt and other contaminants are reduced as the dipstick is not removed to take the sample. Sampling occurs quickly, easier and the analysis is more accurate.

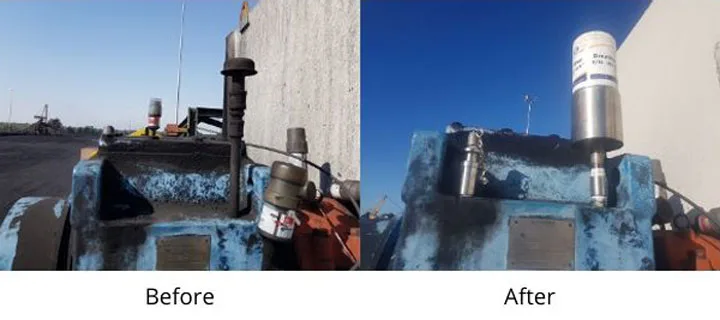

Example 2 - Breathers currently fitted were allowing the ingress of coal dust, water and other contamination to the oil compartments. Much of this was due to the breather being fitted to close to the reservoir and inadequate protection from hosing and ambient conditions.

2. Action

GOSS Engineering fitted Breathers, sample points and dipsticks Assembly’s throughout the machinery on the site. Included during this upgrade was the Raw coal, bypass coal, clean coal and Train load out loops.

3. Outcomes

This has allowed faster and more accurate oil sampling of gear box compartments.

Decreased the amount of contaminates entering the compartments via the breathers due to the splash guards as well as preventing the clogging of the breathers.

Revolutionary

Power Transfer

Download the Magnadrive Handbook.

A world-changing industrial technology that saves energy, reduces operation & maintenance costs and improves system reliability.